About Us

Robotech Automation- Another Name of Expertise

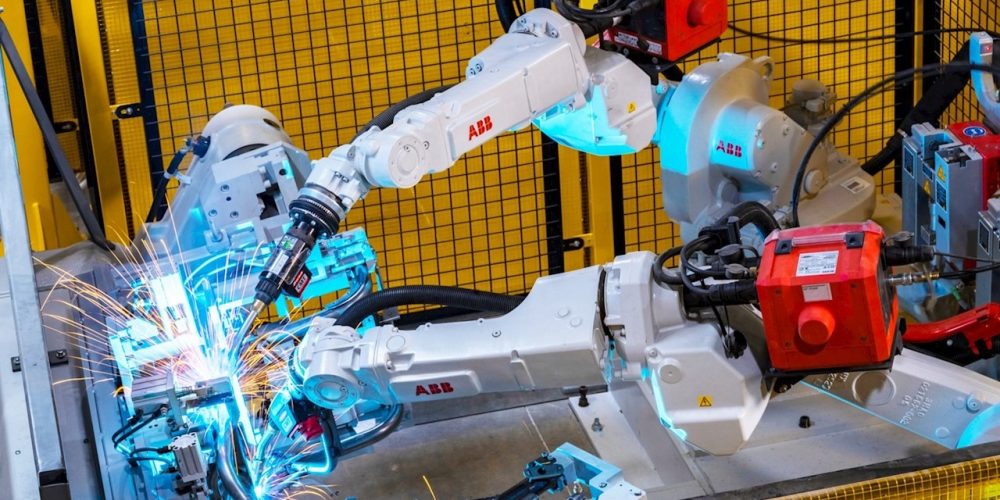

Incepted in the year 2012, at Ghaziabad (Uttar Pradesh, India), we “Robotech Automation Pvt. Ltd.”, are a well-renowned manufacturer and supplier of a comprehensive range of Robotic MIG Welding Cells, Sliding Welding Positioner, Auto TIG Welding Machine, Welding Automation, Assembly And Cutting Automation, Horizontal Welding SPM, Material Handling Systems, Plating Plant, Industrial Conveyor, Industry Trolley, Assembly Line For Console, Hydraulic Press Machine, Assembly And Testing Fixtures, Force And Time Testing Automation, etc. The offered machines are designed and manufactured using the finest quality components with the help of sophisticated technology. These machines are engineered with high precision to meet international quality standards. In addition, these machines are highly appreciated by our clients for features like durability, excellent performance, easy maintenance, simple installation, sturdy construction and longer service life. Available in various technical specifications, these machines are offered at the most reasonable price as per the requirements of clients.

+13

Years Experiance

Our Specialization

Gantry Automation

CNC Machine Tending

Robotics and Automation

Special Purpose Machines

Industrial Robots

Special Purpose machines(SPM’s)

Testing Stations & JIGS

Why Should You Trust Us

Discover seamless integration, exceptional reliability, and unparalleled efficiency. Enhance your operations with our cutting-edge machinery and automation solutions. Partner with us for transformative outcomes.

Partnership approach

We are committed to fostering strong relationships with our customers, grounded in trust, transparency, and the delivery of outstanding products. Our primary goal is to offer value-driven solutions that empower our clients to operate smoothly and expand their businesses.

Industry Expertise

Through our partnerships with a wide range of successful clients, we’ve gained valuable experience and insights across industries such as Automotive, White Goods, Energy, Education, and more. We utilize this expertise in the design of our equipment, providing comprehensive business knowledge as an integral part of our service.

Technical Expertise

Robotechautomation a team of skilled engineers, designers, programmers, and technicians, providing us with a strong technical advantage. Our dedicated professionals play a crucial role in maintaining our technical expertise, giving us a competitive edge in the industry. As Industry 4.0 continues to evolve, our team of traceability and software experts is fully equipped to keep pace with the latest advancements in technology.

Reliable Support and Service

We believe that great automation solutions are just one part of the puzzle. That’s why we’re dedicated to offering reliable support and service that you can count on, long after the installation is finished. Our commitment to reliability begins the moment we start working with you. From the first consultation through to project completion, our experienced team is with you every step of the way, providing expert guidance, responsive communication, and unwavering support.

Proven Track Record

Our wide-ranging portfolio of completed projects showcases our dedication to achieving results that go beyond expectations. Whether it’s small-scale installations or large-scale industrial automation solutions, we have consistently proven our capability to meet and exceed the diverse needs of our clients across multiple industries.

Client-Centric Solutions

At Robotechautomation our commitment to client-centric solutions drives everything we do in the realm of industrial automation. We understand that every client comes with unique needs and challenges, and our approach is centered around addressing those specific requirements with precision and care.

Robotic Waterjet Cutting Cell

Offering You The Best Solution For Your Industrial Applications

Always Open

For You

We are open Mon-Sat from 9AM to 6PM.

Unbeatable

Prices

100% Guarantee of Prices.

We believe in making customers happy rather than making profit.

Professionally Qualified

Team

We Have Qualified Team in the Areas of Application Engineering, Design, Controls, Assembly, Vendor and Servicing.

Solutions We Provide

Gantry automation refers to a robotic system designed with a gantry structure, often used in industrial applications to automate tasks such as material handling, assembly, or packaging. The gantry system typically consists of a rigid frame with a movable platform, allowing the robot to move along multiple axes, providing flexibility and precision. These systems are often used in environments where large, heavy, or intricate materials need to be handled with high accuracy. Gantry automation is commonly seen in industries like manufacturing, logistics, and semiconductor production, offering benefits like increased efficiency, accuracy, and the ability to handle tasks that are difficult or dangerous for human workers.

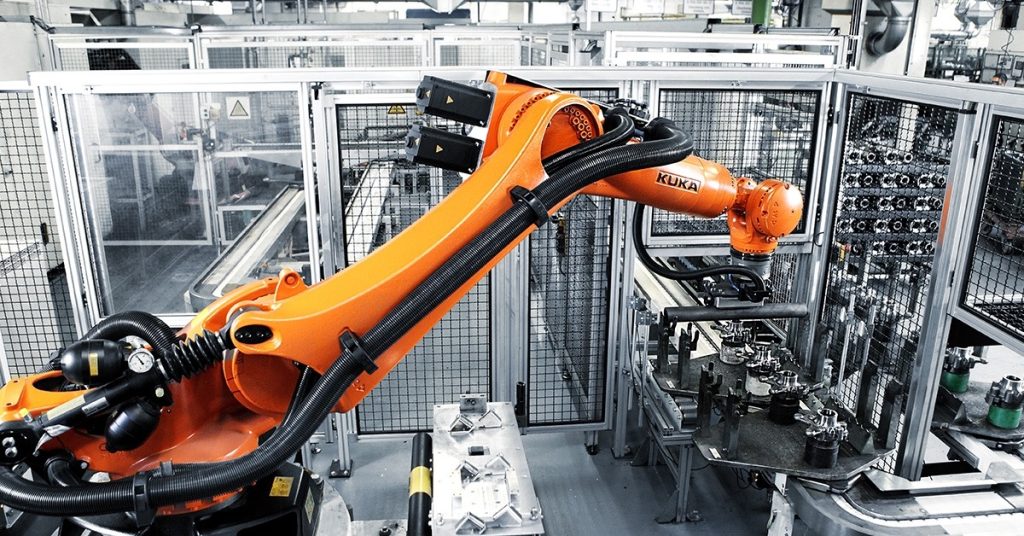

Robotics automation refers to the use of robotic systems to perform tasks typically done by humans, enhancing efficiency and precision in various industries. These robots are programmed to carry out repetitive, dangerous, or complex tasks, such as assembly, packaging, welding, or material handling. Robotics automation is widely used in manufacturing, healthcare, logistics, and agriculture, offering benefits like increased productivity, reduced labor costs, and improved safety. The integration of advanced sensors, AI, and machine learning in robotic systems further boosts their capabilities, allowing for smarter and more flexible automation.

Auto gauging refers to the use of automated systems to measure and monitor the dimensions or quality of a product during manufacturing or assembly. It typically involves sensors, cameras, and other measurement tools integrated with machines that automatically inspect parts for accuracy, ensuring they meet predefined specifications. This process helps improve precision, speed, and consistency while reducing human error and labor costs in industries like automotive, electronics, and metalworking.

Automation peripherals are essential devices that enhance automation systems by improving efficiency, accuracy, and control. These include sensors, actuators, controllers, HMIs, communication devices, cameras, and power supply units. They help automate tasks, reduce errors, save costs, and increase precision across industries, from manufacturing to healthcare and home automation.

Our Clientele Includes:

Make In India

Proudly contributing

to the ‘Make in India’ initiative with innovation and excellence.